The quality of dSLR camera’s seemed to be hitting the max, until now. Below is InVisage’s new’s article:

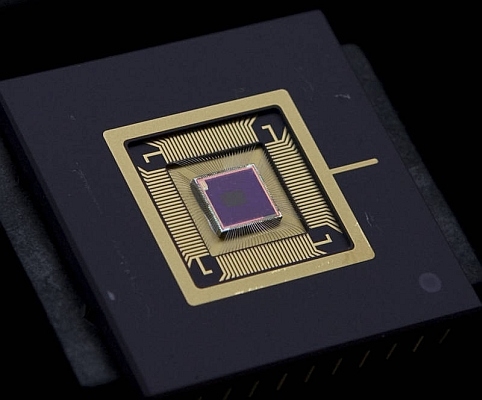

QuantumFilm is applied as a thin film on top of traditional CMOS wafers. This thin film now absorbs all of the photons on the top surface of the pixel. QuantumFilm has 100% fill factor and all of the photons are absorbed in very short depth. This means better light capture in low-light and true-to-life photos.

Today’s image sensors are flawed. And this flaw forces camera users to choose between the convenience of a mobile phone or portable camera and the quality images captured by a large camera. This compromise is required because the current pixel technology is extremely inefficient. The standard silicon pixel will lose 50% of the incoming light to metal lines or transistors blocking the silicon below, commonly called the fill factor. And of the light that does make it through, the silicon itself is only able to convert about 50% of the photons to electrons.This conversion, known as quantum efficiency, cannot be changed. In total, only about 25% of the light that hits the pixel is being converted to an actual image by your camera.

PALM DESERT, Calif., March 22, 2010, DEMO Spring 2010 – Ushering in a new era of high-performance image sensors, InVisage Technologies, Inc. – a venture-backed start- up that is revolutionizing the way light is captured – today announced QuantumFilm. Harnessing the power of custom-designed semiconductor materials, QuantumFilm image sensors are the world’s first commercial quantum dot-based image sensors, replacing silicon. InVisage delivers 4x higher performance, 2x higher dynamic range and professional camera features not yet found in mobile image sensors. The first QuantumFilm-enabled product, due out later this year, solves the crucial challenge of capturing stunning images using mobile handset cameras.

QuantumFilm was developed by InVisage after years of research under the guidance of notable scientist and InVisage CTO Ted Sargent. The technology is based on quantum dots – semiconductors with unique light-capture properties. QuantumFilm works by capturing an imprint of a light image, and then employing the silicon beneath it to read out the image and turn it into versatile digital signals. InVisage spent three years engineering the quantum dot material to produce highly-sensitive image sensors that integrate with standard CMOS manufacturing processes. The first application of QuantumFilm will enable high pixel count and high performance in tiny form factors, breaking silicon’s inherent performance-resolution tradeoff.

“It is becoming increasingly difficult and expensive to develop next-generation image sensors using silicon; essentially, silicon has hit a wall,” says Jess Lee, InVisage President and C.E.O. “The fundamental problem is that silicon cannot capture light efficiently, but until now it has been the only option. The disruptive nature of QuantumFilm builds on silicon’s success in electronics, and elevates its function using new materials that are engineered from the ground up for light capture.”

Silicon-based image sensors – the technology used today for all digital cameras including handheld, professional, mobile phone, security and automotive cameras – capture on average a mere 25 percent of light. QuantumFilm captures between 90-95 percent, enabling better pictures in even the most challenging lighting conditions. This increase in efficiency will deliver improvements across the entire imaging market, allowing QuantumFilm to be the de-facto next generation camera platform. The first target market for QuantumFilm is mobile handsets, where there is the greatest demand for small, high performance image sensors.Just nanometers in size, the quantum dot-based material is deposited directly on top of the wafer during manufacturing. And unlike silicon-based image sensor technologies such as BSI (back-side illumination) and FSI (front-side illumination), QuantumFilm covers 100 percent of each pixel. The material is added as a final wafer-level process, which allows for easy integration into standard semiconductor foundries. The process – akin to coating a layer of photoresist onto a standard wafer – adds minimal cost on top of the standard layers of silicon processes.

“It is safe to say that the industry spends an average of $1 billion for each new generation of pixel technology, all to achieve a single-digit percentage improvement in image quality,” says Tetsuo Omori, senior analyst, Techno Systems Research Co. “The future of imaging is in new materials like QuantumFilm, which will change the competitive landscape and possibly re-ignite the pixel race.”

InVisage was founded in 2006 and is led by industry veterans from the image sensor and advanced semiconductor materials industry. It employs 30 people at its Menlo Park headquarters and has received more than $30 million in funding from RockPort Capital, CharlesRiverVentures,InterWestPartnersandOnPointTechnologies. Itstechnologyis protected by 21 patents and patents pending.

QuantumFilm is ideal for a wide range of image-sensing technologies including security cameras, automotive cameras and military applications. The first QuantumFilm image sensors, targeting high-end mobile handsets and smartphones, will sample in Q4 of 2010.

For more information on InVisage Technologies, please visit its newly-launched web site at www.invisageinc.com. InVisage will be demonstrating its new technology at DEMO Spring 2010 in Palm Desert, Calif., on March 22 and 23. InVisage will also be giving a talk about its technology at Image Sensors Europe 2010 on March 24 in London.

About InVisage Technologies, Inc.

InVisage Technologies, Inc. is a venture-backed fabless semiconductor company based in Menlo Park, Calif. that is developing QuantumFilm, a breakthrough imaging-sensing technology that will replace silicon. Its first product enables the high-fidelity, high resolution images from handheld devices like camera phones and PDAs. Founded in 2006, InVisage Technologies is venture funded by RockPort Capital, Charles River Ventures, InterWest Partners, and OnPoint Technologies. More information is available at www.invisageinc.com.

About DEMO

Produced by the IDG Enterprise events group, the worldwide DEMO conferences focus on emerging technologies and new products innovations, which are hand selected from across the spectrum of the technology marketplace. The DEMO conferences have earned their reputation for consistently identifying cutting-edge technologies and helping entrepreneurs secure venture funding and establish critical business. For more information on the DEMO conferences, visit http://www.demo.com/.

For more information, please contact

Tara Sims siliconPR for InVisage Inc. [email protected] 415 310 5779